The challenge

SMEC was commissioned to provide Geotechnical Design and Construction services on Phase 3 of the harbour’s development. Common to many projects on the eastern coast of Australia, soft soils were present within and surrounding the footprint of significant portions of the harbour. To address this, a surcharging strategy was developed and adopted for improvement of the soft soils surrounding the project.

The original surcharge design for the northern portion of the soft soil improvement zone included a surcharge mound and a batter. The original design required a surcharge mound of up to about 7.5m fill over existing ground levels. The proposed solution, including amendment of the design criteria to better suit the local zone, eliminated the required batter to support the surcharge fill and reduced the fill thickness by up to 2m.

Figure1: The completed wall, shown here, used an innovative vertical retaining system which enabled a smaller footprint.

The solution

When SMEC joined the project, Dr Kianfar’s team reviewed the original surcharge design and developed an alternative design which also included more suitable design criteria for that section of the site.

“We were able to utilise an innovative, flexible Reinforced Soil Wall (RSW) instead of a batter which created a vertical retaining solution. This enabled a smaller footprint than the previous battered surcharge design”, said Dr Kianfar.

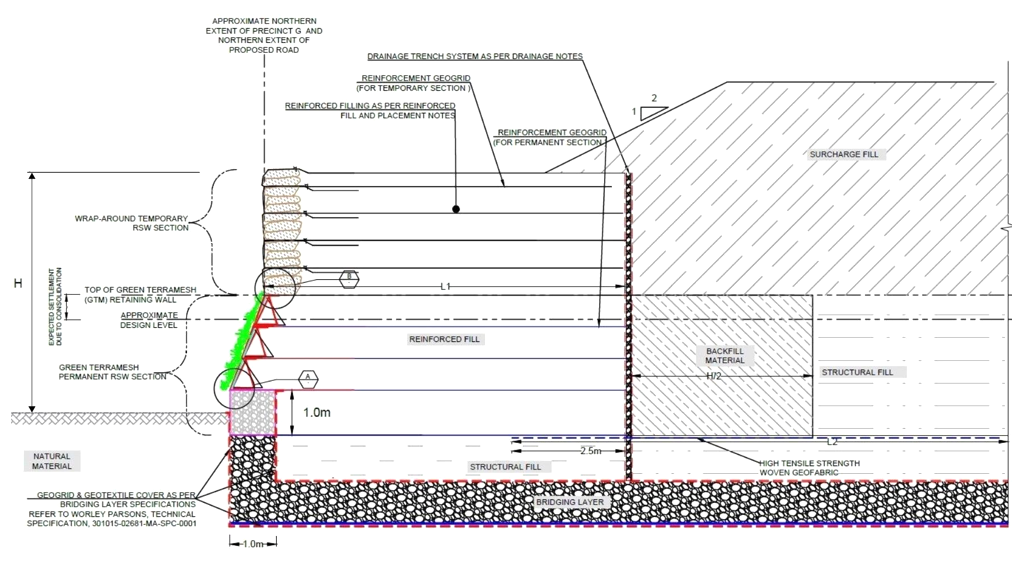

The designed and constructed flexible Reinforced Soil Wall (RSW) comprised of the following three retaining walls over each other:

- A Gabion wall at the base (part of permanent section of the wall)

- A Green Terramesh wall over the Gabion wall (as the second permanent section of the wall)

- A Wrap-Around wall over the Green Terramesh wall (as the temporary section of the wall)

Figure 2: Cross section of the Reinforced Soil Wall (RSW) design.

By challenging conventional uses of existing products, a unique solution was developed to offer our clients a better way forward for their projects.

Dr Kianfar explains, “Each of the three parts of the RSW provides advantages for the project. The gabion wall eliminated the requirement for a toe drain. The Green Terramesh wall has a permanent green face which aesthetically compliments the oval next to the wall and tolerates differential settlements by using Paralink reinforcement. The final layer of wrap-around wall provided a low-cost surcharge structure that could be easily removed following the completion of the soft soil improvement.”

Monitoring of the RSW during the surcharging and consolidation process confirmed the expected behaviour of the wall and proved that the adopted solution was suitable for the project, as the design calculations indicated. Based on our knowledge, the unique combination of the above three walls is a first in Australia, if not in the world.

With over 25 years’ experience in geotechnical and civil engineering, Dr Kianfar completed his PhD degree in geotechnical engineering on soft soil improvement via vertical drains and vacuum preloading through the University of Wollongong, Australia, in 2012. This accomplishment, combined with extensive design and project management experience on projects including the Albion Park Rail Bypass (Early Works) project, has given Dr Kianfar a specialised skill set.

By challenging conventional uses of existing products, a unique solution was developed to offer our clients a better way forward for their project.

Images courtesy of Coastwide Civil.

Related

Insights

"Break down the barriers through the quality of your contribution"

"Break down the barriers through the quality of your contribution"

SMEC Senior Programmer Mobina Zafar was named Young Female Professional of the Year at the Surbana Jurong (SJ) International Awards held in Brisbane, Australia in December 2018.

An engaging and entrepreneurial spirit leads to SMEC

An engaging and entrepreneurial spirit leads to SMEC

A career path leading to SMEC is often a diverse one – that was certainly true for Libby Paholski.

A recipe for success

A recipe for success

If I wasn’t working in engineering, I would definitely be a chef – probably on my way to earning a Michelin star or two!

In pursuit of productivity enhancements and innovation at SMEC

In pursuit of productivity enhancements and innovation at SMEC

A s consultants, we are always trying to help our clients achieve a great outcome on their project. In a competitive market we aim to deliver great outcomes at a competitive cost. To achieve this, we constantly need to increase productivity and find innovative technical solutions.